Professional Manufacturer Of Baked

Whole-set Equipment

News & Media

-

The mixing head of a planetary mixer, such as the attachments (whisk, paddle, dough hook), is typically manufactured with a specific design and edge profile. Unlike traditional kitchen knives or blades, sharpening these attachments may require specialized equipment and expertise. It's important to n...

-

Reducing the noise of a sugar miller machine running can improve the working environment and minimize disturbances. Here are some strategies to reduce the noise generated by the machine: 1. Proper Machine Maintenance: - Regularly inspect and maintain the machine to ensure all components are in g...

-

Learning to use a chocolate coating machine effectively involves a combination of training, practice, and experience. Here are some steps and tips to help people learn how to use a chocolate coating machine proficiently: Read the Manual: Start by thoroughly reading the user manual provided by the m...

How to Install Candy Machine?

Installing a candy machine can vary depending on the type and model of the machine, but here are some general steps that can be followed:

Choose a location: Choose a location that is visible and easily accessible to customers. Ensure there is enough space for customers to approach the machine and make their selection.

Prepare the space: Clear the area where the candy machine will be placed, and make sure the floor is level. If necessary, install a sturdy base or stand to support the machine.

Assemble the machine: Follow the manufacturer's instructions to assemble the machine. This may involve attaching the base, mounting the dispenser, and connecting any electrical components.

Load the candy: Fill the dispenser with candy, following the manufacturer's instructions for the correct amount and type of candy to use.

Test the machine: Once the candy is loaded, test the machine to ensure it is functioning correctly. Make sure the candy is dispensing properly and that the machine is accepting payment (if applicable).

Secure the machine: To prevent theft or tampering, secure the machine to the base or floor using bolts or other fasteners.

Set the price: If the machine is designed to accept payment, set the price for the candy and program the machine accordingly.

Add signage: Place clear signage on or near the machine to indicate the type of candy available, the price, and any payment methods accepted.

Overall, installing a candy machine requires careful planning and attention to detail. By following these general steps and the manufacturer's instructions, you can install a candy machine that is both functional and attractive to customers.

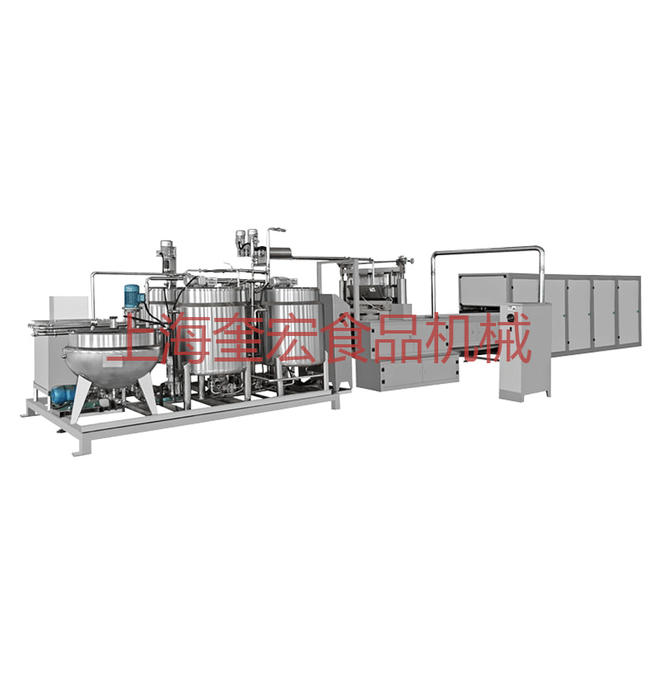

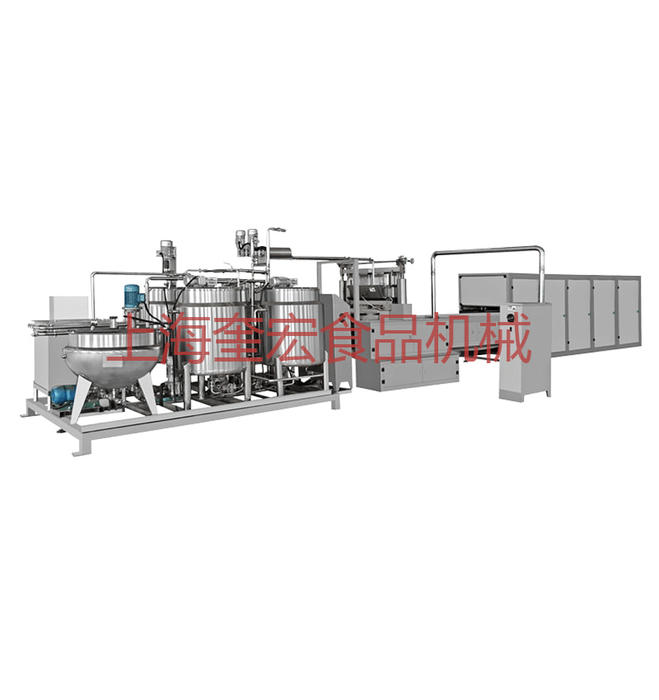

The Application of Candy Machine

A candy machine is a type of equipment used to produce a wide variety of candies, including hard candies, gummies, chocolates, and more. The application of a candy machine depends on the type of candy being produced, but generally includes the following steps:

Mixing: The candy ingredients are mixed together in a heated kettle to form a syrup or slurry. The kettle may be heated by gas, electric, or steam.

Cooking: The candy mixture is heated to a specific temperature and cooked for a set period of time. This process may involve continuous stirring to prevent the mixture from burning.

Cooling: The candy mixture is then cooled down to a specific temperature to allow it to solidify. This may be done in a cooling tray or by pouring the mixture onto a cooling table.

Shaping: The candy is then shaped into the desired form using molds, cutters, or extruders.

Coating: Some candies may be coated with chocolate, sugar, or other coatings to enhance their flavor and appearance.

Packaging: The finished candies are then packaged in boxes, bags, or other containers for storage and distribution.

Candy machines are commonly used in the food industry, including candy factories, bakeries, and other confectionery businesses. They are designed to produce candies efficiently, with consistent quality and uniformity in shape, size, and texture.

English

English