Professional Manufacturer Of Baked

Whole-set Equipment

Food Machinery

-

Double -action and two-speed flour spiral mixer

Doubel -action and two -speed flour mixer There are high speed, low speed and inching status in KH series double-action & double-speed dough maker through changing the motor speed. The vertical stainless steel spiral mixer and basket are driven by the chain. All the parts touching with dough are made of stainless steel or electro-plated on its surface and tally with national sanitary standar...

-

Deck Oven

Deck oven deck oven both electrical and gas are available this is an ideal equipment for the bakery shop Main parameter Model Specifications Size(mm) Voltage Power Tray size KH-306D Three layers of 6 plate 1340*1010*1790 380v/50hz 18kw 40*60cm KH-309D Three layers of 9 plate 1740*1010*1790 380v/50hz 27kw 40*60cm KH-312D Three layers of 12 plate 1...

-

Rotary Oven

The hot-blast rotary baking oven is the ideal equipment for your cookies, cake, bread, biscuit and other foods. It is with excellent characteristics as follows: even fire color, the high technology makes high efficient power-saving and the energy fully utilized. and we adopt the export spare parts with excellent warm and rigor airtight quality and best system for keeping warm, and reduce the quan...

-

Biscuit Dough Mixer

Product Introduction The dough making machine is a machine that mixes flour and water or other ingredients into dough. It can be used singly or work with other equipment. It is widely applied for making dough for various cakes, biscuits, bread and steamed bread in hotels, restaurants, canteens, etc. It can also be used for mixing other materials. Main Parameter Model Capacity Mixing tim...

-

High speed sugar miller machine

High speed sugar miller machine Main parameter : 1.crashing granulated sugar :150kg/h 2.Working temperature : 50 ℃ 3.Production capacity :25-75kg/h 4.Tolerance : ≦5% 5.Principal axis speed: 5600 rotate /min 6.Power : 4kw 7.Crashing fineness : 25-300 mesh 8.Working noise : ≦85 decibel 9.Machine weight : 200kg/h 10.Machine size : 1360*800*600mm

-

Compressed Biscuit Machine

Main Parameter Production capacity Voltage Oil cylinder Dimension 1-3T/shift 380V 15-25Mpa 900×800×1400mm

-

Automatic Cake Making Machine

KH-DGX-800 Our full automatic cake production line is research and developed on the basis of Europe's advanced equipment, and colligate with the real condition of individual workshop .the full automatic cake line gathers the electricity, light and machine together .with the merits of high automatic, large capacity, fewer workers, and fewer workers touched with the products .long quality guarantee...

-

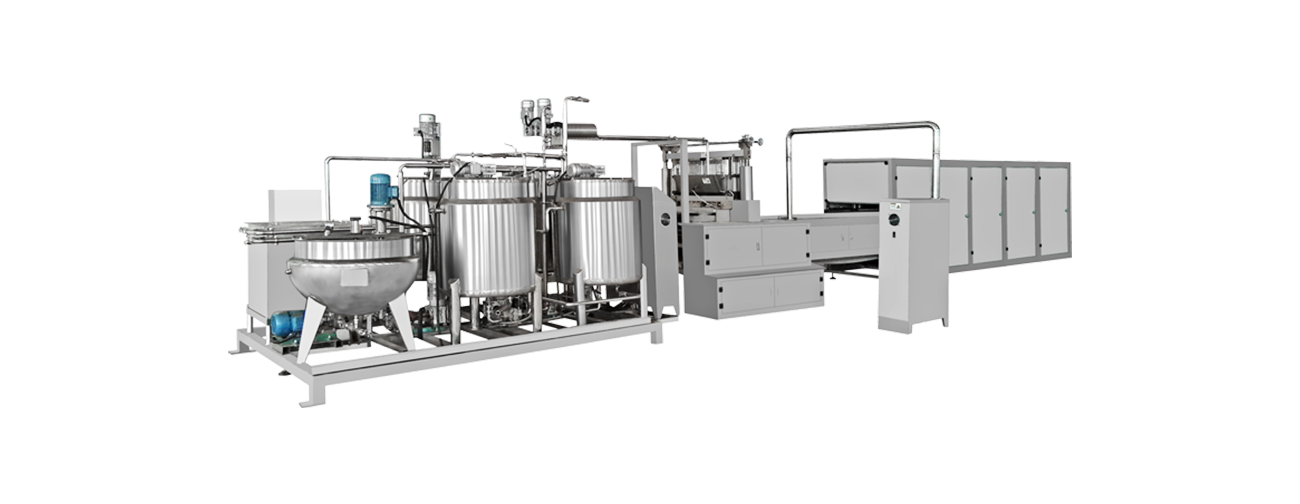

swiss roll & layer cake production line

The equipment consists of agitator, oil brushing machine, depositing and forming machine, gas heating tunnel oven with steel belt, return conveying mesh belt, slicing device, sandwich device, cake overturn device, pressing device, transverse cutting device, cooling conveyor, etc. Characteristic: The size, weight and flavor can be changed, layer cake production also available; high automation, eas...

-

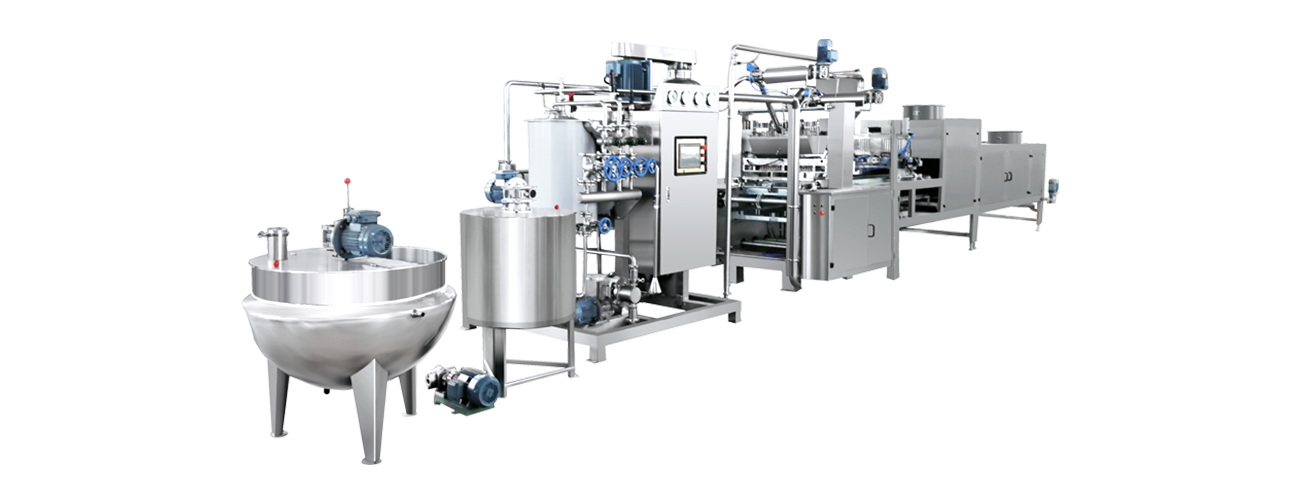

Jelly Candy Production Line

KH150/300/450/600 Candy depositing line is based on the 3rd generation machine; it is advanced equipment which can continuously produce various kinds of hard candies under a strict sanitary condition. This line can automatically produce high-quality hard candy, such as single color candy, two-color candy, three-color candy, crystal candy, central-filling candy, etc. The whole line is according to...

Food Machinery Supplier

Food Machine Manufacturers and Food Machine Suppliers in China

, our factory Located at the forward position for China's economic development-Shanghai Chemical Industrial Zone, At the same time, Shanghai Kuihong machinery manufacturing Co, Ltd is a comprehensive enterprise that specializes in research development and production of food machinery, integrating technology, industry, and trade. Featured by advanced technology, high quality, centralized functions, and simple operation.

Cake Machine

Main Frame And Operation Principle

The machine adopts computer programming, compact structure, concentrate function, simple operation, adopts the cylinder as the power, and with the photo & electric tracking, automatic quantitative extruder, high capacity, high precision. This machine is one of the advanced equipment for making custard cakes, cupcakes, etc.

Learn More

Cookies Biscuit Machinery

Main Function And Usage

The PLC cookies machine is the new kind of cookie shapes forming machine, which is automatically controlled. You can set the cookie forming ways(depositing or wire cutting), working speed, space between cookies, etc by touch screen. We have dozens of nozzle types for choice, or we can customize the special nozzles as your requirements. This machine used a SERVO motor, for baking, you can use the rotary oven, deck oven, or tunnel oven. It is the new equipment on the market.

Learn More

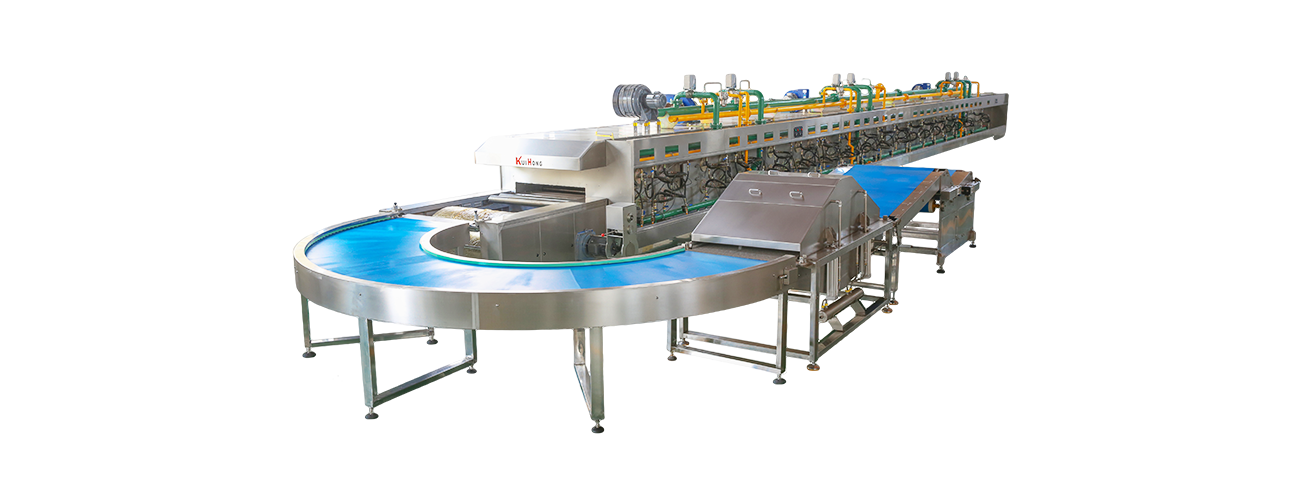

Rotary Egg Roll Machine

Main Function And Usage

The machine in the picture is the new type of egg roll making equipment. It used international advanced technology and adopted natural gas as the fuel to make out the new type of fully automatic egg roll making machine. This unit solved the problem of the high cost of the old type units. This unit includes the mixing system, material filling system, color mixing system, core filling system, transmission system, cooling system, etc.

Learn MoreNews & Media

-

The mixing head of a planetary mixer, such as the attachments (whisk, paddle, dough hook), is typically manufactured with a specific design and edge profile. Unlike traditional kitchen knives or blades, sharpening these attachments may require specialized equipment and expertise. It's important to n...

-

Reducing the noise of a sugar miller machine running can improve the working environment and minimize disturbances. Here are some strategies to reduce the noise generated by the machine: 1. Proper Machine Maintenance: - Regularly inspect and maintain the machine to ensure all components are in g...

-

Learning to use a chocolate coating machine effectively involves a combination of training, practice, and experience. Here are some steps and tips to help people learn how to use a chocolate coating machine proficiently: Read the Manual: Start by thoroughly reading the user manual provided by the m...

-

The primary purpose of a chocolate depositing machine is to automate the process of depositing or molding chocolate into specific shapes or forms. It is commonly used in the chocolate and confectionery industry to produce various chocolate products, such as bars, pralines, truffles, filled chocolate...

-

The working principle of a wafer roll machine involves a series of steps to produce cylindrical or tube-shaped wafer rolls. Here's a general overview of the working principle: Batter preparation: The machine is equipped with a batter mixing system where the wafer batter is prepared. The batter ...

-

An aerated mixer, also known as an air mixer or air-driven mixer, is a type of mixing equipment that utilizes compressed air to agitate and blend liquids or powders. It is commonly used in various industries, including food and beverage, pharmaceuticals, cosmetics, and chemical processing. The aerat...

English

English